Dryer section optimisation

Dryer section optimisation

Paper and board machines

We can achieve considerable improvements in runnability with small actions performed over a short time. At the same time, your energy consumption will decrease. Compared to new investments, grinding, balancing and coating are extremely cost-effective measures and will also improve the quality of your paper.

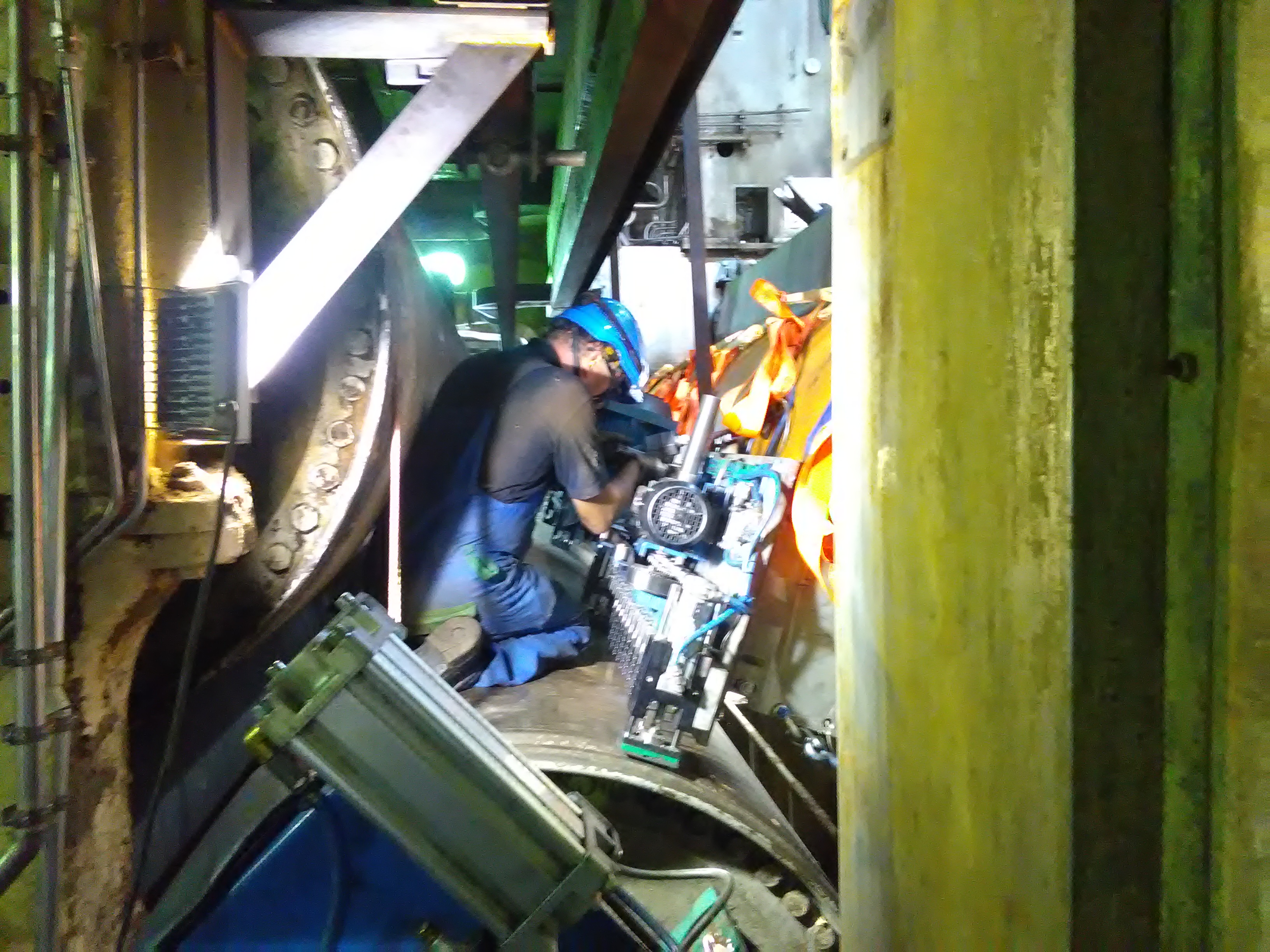

Performing machining, coating and balancing as an on-site service will reduce your downtime multifold compared to removing the cylinder from the machine. PR Rolls has great capacity for performing machining, coating and balancing simultaneously, shortening your downtime even further. For example, one of our projects involved the machining, coating and balancing of 45 dryers in just 12 days.

When you need a stabiliser, suction box or pocket ventilation device, we work together with Runtech to ensure your satisfaction.

We have solved more than a thousand cylinder problems in Finland and all over the world. When you want to optimise your machine’s dryer section within a specific timetable, please ask us for an estimate.

Find out more about the coating and drilling of vacuum rolls here!

See our video on drilling vacuum rolls and fill in the contact form!